Get the free haccp flow diagram template

Show details

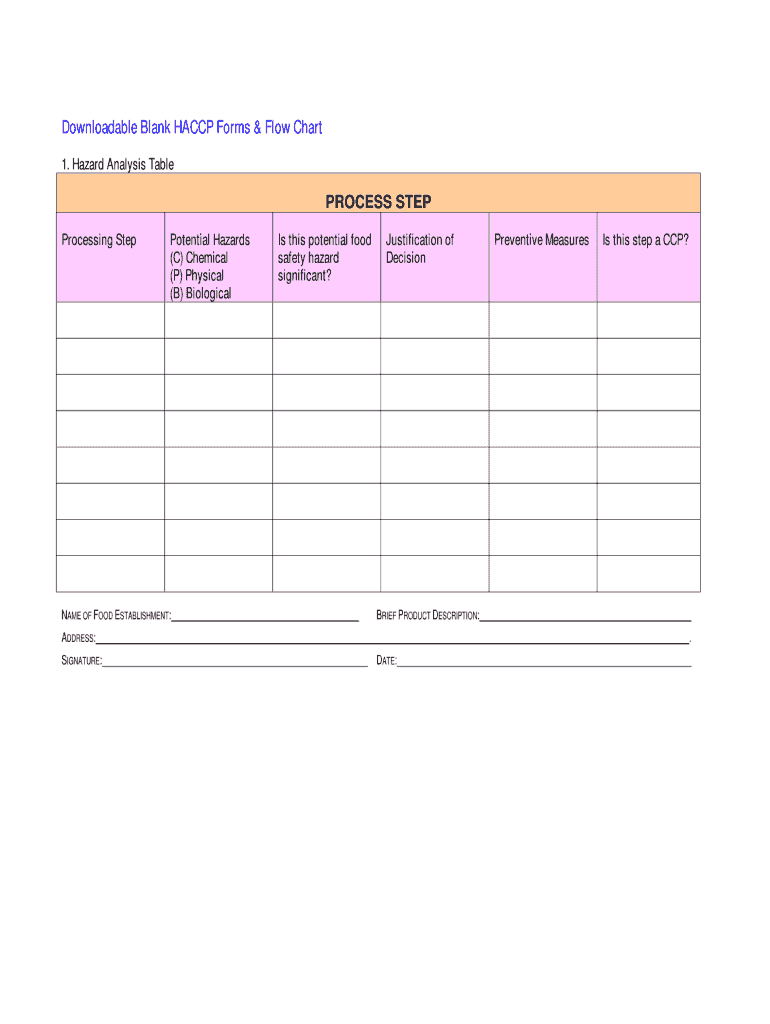

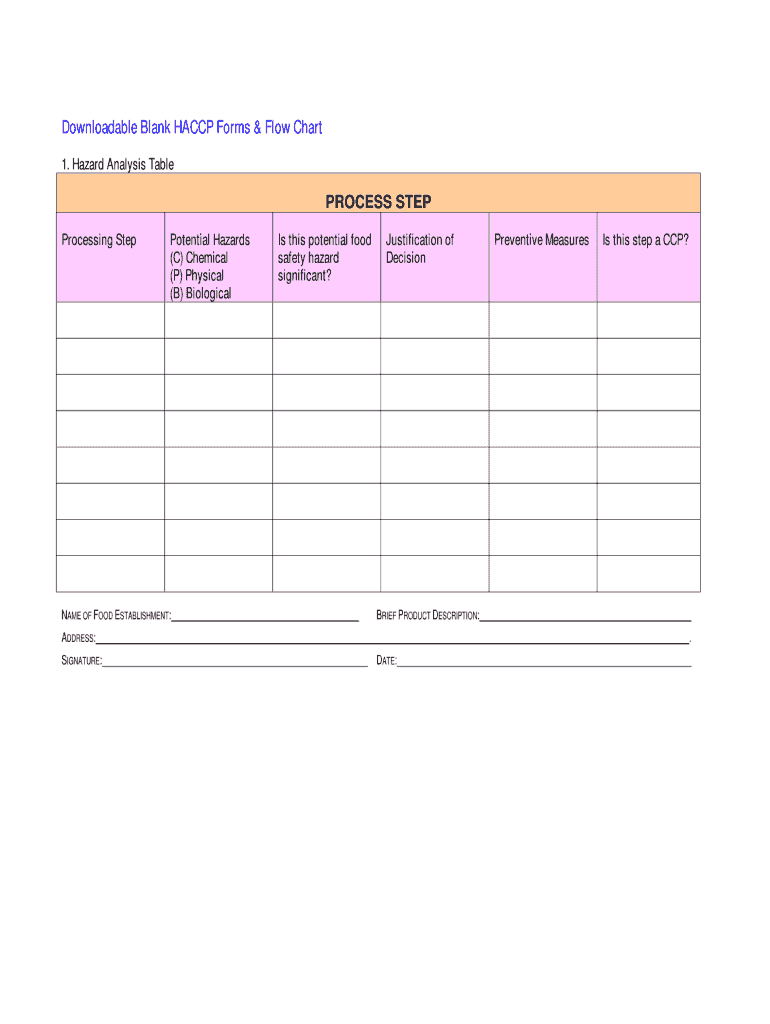

Downloadable Blank HACCP Forms & Flow Chart 1. Hazard Analysis Table PROCESS STEP Processing Step Potential Hazards Chemical (P) Physical (B) Biological Is this potential food safety hazard significant?

pdfFiller is not affiliated with any government organization

Get, Create, Make and Sign haccp flow chart template form

Edit your haccp flow chart form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your forms flow chart form via URL. You can also download, print, or export forms to your preferred cloud storage service.

How to edit downloadable blank haccp forms online

Use the instructions below to start using our professional PDF editor:

1

Set up an account. If you are a new user, click Start Free Trial and establish a profile.

2

Upload a document. Select Add New on your Dashboard and transfer a file into the system in one of the following ways: by uploading it from your device or importing from the cloud, web, or internal mail. Then, click Start editing.

3

Edit flow haccp form. Rearrange and rotate pages, add and edit text, and use additional tools. To save changes and return to your Dashboard, click Done. The Documents tab allows you to merge, divide, lock, or unlock files.

4

Save your file. Choose it from the list of records. Then, shift the pointer to the right toolbar and select one of the several exporting methods: save it in multiple formats, download it as a PDF, email it, or save it to the cloud.

pdfFiller makes working with documents easier than you could ever imagine. Try it for yourself by creating an account!

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out forms flow chart fillable

How to fill out NYC HACCP Forms & Flow Chart

01

Gather necessary information about your food establishment, including menus and food preparation methods.

02

Obtain the appropriate HACCP forms and flow charts from the NYC Department of Health website or local office.

03

Identify potential hazards in your food handling process and document them in the forms.

04

Map out the flow of food within your establishment using the flow chart, from receiving to serving.

05

Establish critical control points (CCPs) in your process where you can prevent, eliminate, or reduce hazards.

06

Set critical limits for each CCP, specifying the acceptable criteria that must be met.

07

Implement monitoring procedures for each CCP to ensure they stay within critical limits.

08

Develop corrective actions for each CCP, detailing what steps will be taken if critical limits are not met.

09

Outline verification procedures to ensure the HACCP plan is working effectively.

10

Review and update the forms and flow chart regularly or as changes occur in the menu or food process.

Who needs NYC HACCP Forms & Flow Chart?

01

Food service establishments operating in New York City, including restaurants, catering services, and food trucks.

02

Food manufacturers that produce products meant for sale and consumption, including packaged goods.

03

Schools and institutions that serve food to students and staff.

04

Any business involved in the distribution or handling of food products.

Fill

gov haccp forms

: Try Risk Free

People Also Ask about haccp forms chart

How do I write a simple HACCP plan?

The 7 steps of writing the HACCP Plan are: Set up critical limits. Build a monitoring procedure system for CCPs. Identify corrective action procedures. Establish verification procedures.

How do you create a HACCP flow chart?

How to create a HACCP flow chart with 5 steps? Define all processes in your company. List all HACCP process steps. Define Control Points and Critical Control points. Define control measures. Verify your HACCP flow chart.

What is a flow diagram in HACCP?

A flow diagram is a document that should consist of every aspect or activity of a production process in making a product. This typically begins with receiving meat, ingredients, and packaging – then continues through the steps of making a product and concludes with packaging, storage and distribution.

What are the 7 steps of a HACCP flow chart?

Seven basic principles are employed in the development of HACCP plans that meet the stated goal. These principles include hazard analysis, CCP identification, establishing critical limits, monitoring procedures, corrective actions, verification procedures, and record-keeping and documentation.

What is a HACCP Process Flow Diagram?

A HACCP flow chart represents the flow of food materials in your food business starting from receiving any raw material to serving your finished products. HACCP food safety system requires a detailed and comprehensive food flow chart to properly identify the associated hazards in your manufacturing process.

How do I create a HACCP document?

The 7 steps of writing the HACCP Plan are: Set up critical limits. Build a monitoring procedure system for CCPs. Identify corrective action procedures. Establish verification procedures.

Our user reviews speak for themselves

Read more or give pdfFiller a try to experience the benefits for yourself

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I get haccp forms chart online?

The premium version of pdfFiller gives you access to a huge library of fillable forms (more than 25 million fillable templates). You can download, fill out, print, and sign them all. State-specific gov haccp chart and other forms will be easy to find in the library. Find the template you need and use advanced editing tools to make it your own.

How do I complete gov hazard haccp chart online?

pdfFiller has made it simple to fill out and eSign gov haccp flow. The application has capabilities that allow you to modify and rearrange PDF content, add fillable fields, and eSign the document. Begin a free trial to discover all of the features of pdfFiller, the best document editing solution.

How do I edit control haccp chart online?

The editing procedure is simple with pdfFiller. Open your haccp chart template in the editor. You may also add photos, draw arrows and lines, insert sticky notes and text boxes, and more.

What is NYC HACCP Forms & Flow Chart?

NYC HACCP Forms & Flow Chart are documentation tools used in New York City to outline Hazard Analysis Critical Control Point (HACCP) plans for food safety management in food establishments. They provide a structured process for identifying and controlling food safety hazards.

Who is required to file NYC HACCP Forms & Flow Chart?

Food establishments that handle potentially hazardous foods and are required to have a HACCP plan, including certain restaurants, food manufacturers, and catering services, must file NYC HACCP Forms & Flow Chart.

How to fill out NYC HACCP Forms & Flow Chart?

To fill out NYC HACCP Forms & Flow Chart, one must identify food safety hazards associated with their processes, establish critical control points, set monitoring procedures, determine corrective actions, and document each step clearly in the forms provided.

What is the purpose of NYC HACCP Forms & Flow Chart?

The purpose of NYC HACCP Forms & Flow Chart is to enhance food safety by systematically identifying, evaluating, and controlling hazards in food production, ensuring compliance with health regulations and protecting public health.

What information must be reported on NYC HACCP Forms & Flow Chart?

The information required on NYC HACCP Forms & Flow Chart includes a detailed description of the food products, processes, critical control points, monitoring procedures, corrective actions, and verification methods to ensure food safety.

Fill out your NYC HACCP Forms Flow Chart online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Gov Haccp Flow Chart is not the form you're looking for?Search for another form here.

Keywords relevant to forms flow chart blank

Related to haccp flow chart example

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.